Versatile Dif-Jet Gas Mixing device for Air, Oxygen, Ozone, Carbon Dioxide, and Nitrogen gases

Aeration is the heart of most industrial and municipal wastewater treatment. Fortrans offers a new, cutting-edge solution. Dif-Jet™ aerators are efficient, non-fouling and are suitable for many applications requiring mixing of air – oxygen or ozone into water.

Advanced Dif-Jet™ Aerators For Wastewater – Aquaculture – Aquaponics – Hydroponics – Ozonation – Deoxygenation

Dif-Jets efficiently mix any water soluble gas into high solids water without fouling.

Dif-Jets complete aeration systems operate with air or pure oxygen.

Dif-Jet for carbon dioxide based complete package pH Control Systems- 5 Models

Dif-Jet devices for incorporation into ozone feed system. No venture effect needed.

Dif-Jets are easily used in sidestream applications.

Patented Dif-Jet is available in stainless steel and PVC.

Dif-Jet™ AERATORS PROVIDE MIXING, CIRCULATION & AERATION

LOW PRESSURE OPERATION: 5 TO 25 PSI

LONG SERVICE LIFE – NO PARTS THAT BREAKDOWN

STAINLESS STEEL Dif-Jets™ FOR OZONE APPLICATIONS

Dif-Jet aerators are installed above water surface to pipe aerated water into any depth without increasing air or oxygen pressure. Dif-Jet Aerators are easy to access and lower maintenance costs compared to traditional diffusers.

Dif-Jet™ aerators may be installed sequentially or in a manifold for large aeration requirements.

Dif-Jet™ aerators may be used to replace existing bubble aerators in aquaculture, hydroponics and aquaponics to eliminate fouling and lower energy costs.

Dif-Jet™ aerators enhance production efficiencies in biological manufacturing processes by adding air or oxygen to speed up such processes without in-tank diffusers.

Dif-Jet™ stainless steel aerators are used for feeding ozone for odor control or sterilization of water

Stainless steel Dif-Jet™ aerators are used to mix nitrogen gas into water to deoxygenate water in oil drilling operations. The technology is also efficient at deep well deoxygenation.

Dif-Jet aerators are very efficient for wastewater produced by gold mining operations.

Offer direct aeration into a pressurized (2-3 psi) flowing stream of water without fouling or clogging. In addition, the low cost technology may be incorporated into floating or fixed basin aeration systems.

- May be installed upstream or downstream on piped flowing water without fouling.

- Low cost floating systems are easily configured to aerate water to any depth. The modular floating systems are easy to configure to aerate at different depths.

- Dif-Jet™ aeration systems can be equipped with a Dissolved Oxygen Controller and DO probe to save energy by controlling the aeration process.

- May be installed on a manifold for very large aeration requirements or for pumping aerated water to directed locations within a treatment plant or for multiple outlets within an oxidation ditch or final aeration basins.

- Are ideal for operators of industrial wastewater plants who are paying surcharges to municipal wastewater treatment plants for high Biochemical Oxygen Demand (BOD) or Chemical Oxygen Demand (COD). Dif-Jet™ aerators and aerator systems are easily installed at existing facilities in order to eliminate these costly surcharges.

Benefits of Pure Oxygen Aeration

The DiF-Jet™ may be used with air or pure oxygen. Pure oxygen aeration offers lower initial cost and many verifiable benefits:

- Easily increase organic plant loading and treatment capacity in an energy-efficient and cost-effective way. DiF-Jet™ aerators feature very high oxygen transfer efficiency –- no expensive upgrades to blower systems or air compressors required with corresponding increases in power consumption as well. Help eliminate BOD and COD surcharges and EPA fines.

- Air contains 21% oxygen and 78% nitrogen. The nitrogen competes with the oxygen for solubility requiring higher capacity blowers. The nitrogen strips out volatile compounds which cause odor problems for many facilities.

- Increased bacterial respiration with high-purity oxygen carries over to other areas and may increase overall operational efficiencies.

Dif-Jet™ Non-Fouling Floating Aerato with 3 discharge configurations and Pro-Jet™ nozzles

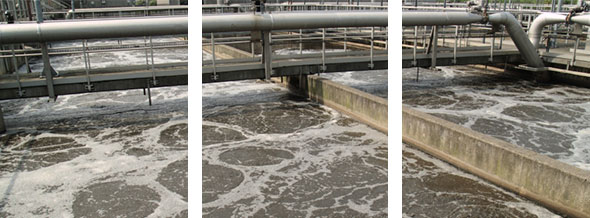

Dif-Jet™ Aerator in Final Aeration Basin

For additional information on our industrial and municipal aerators for wastewater, contact Fortrans, Inc.